Overview

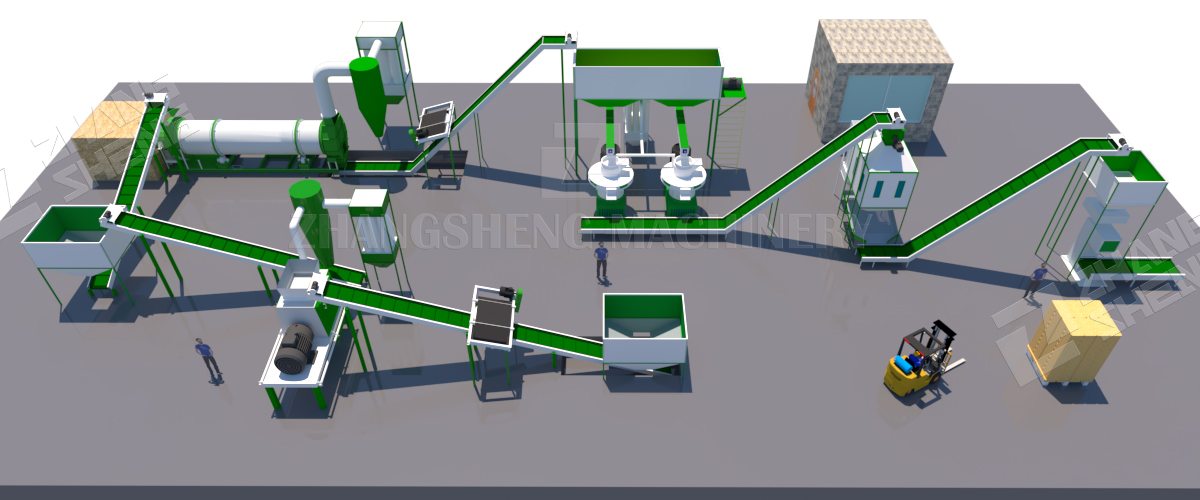

The sawdust pellet line contains all the processes from raw materials to pellets, including crushing, drying, pellet making, cooling and packing, and the capacity is 1 to 10 tons per hour. Wood sawdust pellet have high thermal value, less gray, low cost, small volume, easy to transport and less pollution. With the shortage of coal, oil and other energy sources, the market demand for wood pellets is increasing, the prospect of this project is very good.Market analysis

The utilization rate of finished pellets is very high, which can be directly used in small and medium heating centers and large power plants. The raw materials of the wooden pellet production line can be waste wood. In this case, the waste wood can be used circulating and is very environmentally friendly. Due to the current population growth and energy shortage, pellets can be used directly to provide energy in power plants, and the EU and South American countries have relatively resource shortage. Therefore, the development prospects of the wood pellet production line are very good and the profit is very large.

Why Choose US

1. We are not only device suppliers, but we can also provide suitable solutions according to customer requirements. 2. Our professional knowledge and rich experience help customers increase economic benefits. 3. We fully understand the industry trend, which can provide customers machines with high quality.Process Flow

Case

We have 20 years experience in sawdust pellet line, the pellets production line has been export to Spain, Mexico, Georgia, Malaysia, Turkey and so on, we can provide suitable proposals for customers.2. Hammer mill process small wood chips with a diameter of less than 20mm into sawdust with a diameter of less than 8mm.(Sawdust pellet line doesn't need this process)Primary crushing stage process tree trunks and logs with a diameter of less than 50cm, into small wood chips within 20mm.

We have 20 years experience in sawdust pellet line, the pellets production line has been export to Spain, Mexico, Georgia, Malaysia, Turkey and so on, we can provide suitable proposals for customers.2. Hammer mill process small wood chips with a diameter of less than 20mm into sawdust with a diameter of less than 8mm.(Sawdust pellet line doesn't need this process)Primary crushing stage process tree trunks and logs with a diameter of less than 50cm, into small wood chips within 20mm.

4. The pellet mill makes dry sawdust into pellets, and the output of a single machine can reach 3t/h.

4. The pellet mill makes dry sawdust into pellets, and the output of a single machine can reach 3t/h. 3. The optimum moisture content for granulation is 12-18%. The dryer reduces the wood sawdust moisture from 20%-60% to 12-18%.

3. The optimum moisture content for granulation is 12-18%. The dryer reduces the wood sawdust moisture from 20%-60% to 12-18%. 5. The cooling system cools the pellets from 70-90 ℃ to room temperature, and the hardness of the pellets will become stronger. 6. Pack the qualified pellets from 10kg/100kg or 1 ton into a plastic bag, and then sew with a thermoplastic sealing machine to make the pellets dry and waterproof.

5. The cooling system cools the pellets from 70-90 ℃ to room temperature, and the hardness of the pellets will become stronger. 6. Pack the qualified pellets from 10kg/100kg or 1 ton into a plastic bag, and then sew with a thermoplastic sealing machine to make the pellets dry and waterproof.

Note: This is a conventional simple biomass pellet production line, we can customize different pellet production plans for you according to different sites, raw materials, output and budget. As a leading pellet machine manufacturer in China, ZhangSheng has rich experience in pellet machine manufacturing, and can build a unique pellet mill for you according to the actual situation.

Note: This is a conventional simple biomass pellet production line, we can customize different pellet production plans for you according to different sites, raw materials, output and budget. As a leading pellet machine manufacturer in China, ZhangSheng has rich experience in pellet machine manufacturing, and can build a unique pellet mill for you according to the actual situation.FAQ

1.Is your company a trading one or a factory? Factory and trade (we have our own factory site.)we can supply different kinds of solution for forest with reliable quality and good price machines. 2.Which payment terms are you accepted? Confirm details of the order, 30% deposit, arrange to produce, pay the balance before shipment. 3.When to deliver the goods after the order is placed? It depends on the quantity of the products. Generally we can arrange shipment after 15 working days 4.Does your company accept customization? We have excellent design team, we can do as customer needs,make logo or label for customers,OEM is available.